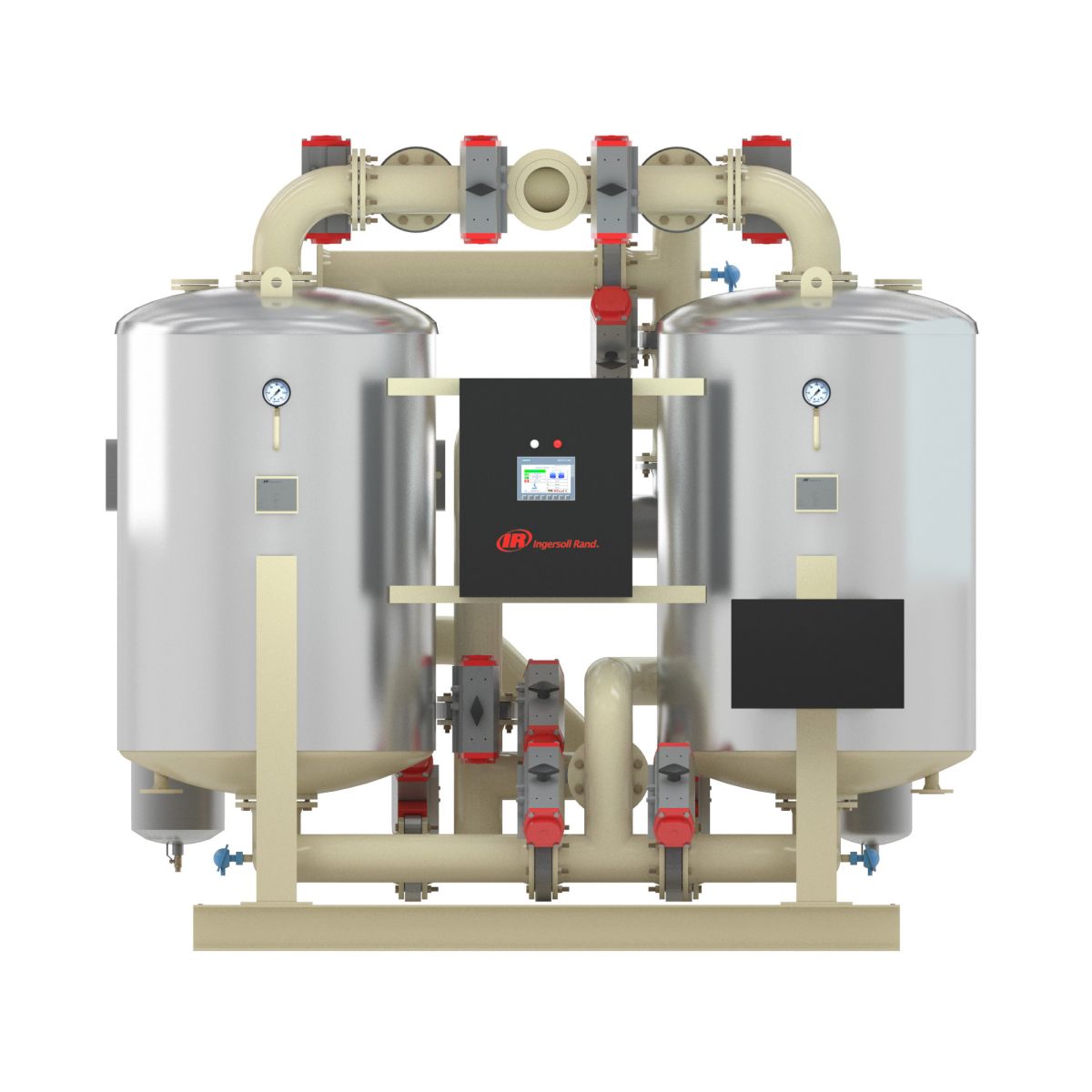

Máy sấy hút ẩm không dùng nhiệt HL sử dụng tháp hút ẩm đôi với các van được bố trí hợp lý để làm khô khí nén. Công nghệ đơn giản của máy sấy không dùng nhiệt chuyển một phần khí nén khô sang tháp ngoại tuyến. Không khí khô sau đó sẽ đi qua và tái tạo chất hút ẩm. Mặc dù chi phí vận hành cao hơn so với máy sấy khô hút ẩm có gia nhiệt nhưng dòng HL yêu cầu vốn đầu tư thấp nhất.

|

Model |

Capacity m3/ min (scfm) |

Length x Width x Height mm (in) |

Weight kg (lb) |

Connection Air In/ Out |

|

HL90 |

2.5 (90) |

762 (30.0) x 1,029 (40.5) x 1,603 (63.1) |

215 (475) |

1″ NPT |

|

HL120 |

3.4 (120) |

762 (30.0) x 1,029 (40.5) x 1,603 (63.1) |

255 (563) |

1″ NPT |

|

HL160 |

4.5 (160) |

813 (32.0) x 1,130 (44.5) x 1,679 (66.1) |

321 (707) |

1 1/2″ NPT |

|

HL200 |

5.7 (200) |

813 (32.0) x 1,130 (44.5) x 1,679 (66.1) |

332 (731) |

1 1/2″ NPT |

|

HL250 |

7.1 (250) |

813 (32.0) x 1,232 (48.5) x 1,697 (66.8) |

394 (869) |

1 1/2″ NPT |

|

HL300 |

8.5 (300) |

813 (32.0) x 1,232 (48.5) x 1,697 (66.8) |

419 (924) |

2″ NPT |

|

HL400 |

11.3 (400) |

919 (36.2) x 1,334 (52.5) x 1,722 (67.8) |

506(1,115) |

2″ NPT |

|

HL500 |

14.2 (500) |

1,008 (39.7)x 1,435 (56.5) x 2,096 (82.5) |

709(1,564) |

2″ NPT |

|

HL600 |

17.0 (600) |

1,078 (42.4)x 1,435 (56.5) x 2,096 (82.5) |

755(1,664) |

2″ NPT |

|

HL800 |

22.7 (800) |

1,302 (51.3)x 1,626 (64.0) x 2,226 (87.6) |

915(2,017) |

3″ NPT |

|

HL1000 |

28.3 (1,000) |

1,302 (51.3)x 1,626 (64.0) x 2,226 (87.6) |

1,015 (2,237) |

3″ NPT |

|

HL1200 |

34.0 (1,200) |

1,302 (51.3)x 1,626 (64.0) x 2,226 (87.6) |

1,100 (2,424) |

3″ NPT |

|

HL1500 |

42.5 (1,500) |

1,391 (54.8)x 1,981 (78.0) x 2,032 (80.0) |

1,349 (2,974) |

4″ FLG |

|

HL1800 |

51.0 (1,800) |

1,540 (60.6)x 2,134 (84.0) x 2,334 (91.9) |

1,771 (3,905) |

4″ FLG |

|

HL2100 |

59.5 (2,100) |

1,540 (60.6)x 2,134 (84.0) x 2,334 (91.9) |

1,941 (4,279) |

4″ FLG |

|

HL2700 |

76.4 (2,700) |

1,550 (60.8)x 2,134 (84.0) x 2,334 (91.9) |

2,234 (4,926) |

4″ FLG |

|

HL3300 |

93.4 (3,300) |

1,676 (66.0) x 2,440 (96.0) x 2,540 (100.0) |

1,338 (2,950) |

6″ FLG |

|

HL4000 |

113.3 (4,000) |

1,676 (66.0) x 2,440 (96.0) x 2,540 (100.0) |

1,361 (3,000) |

6″ FLG |

|

HL5000 |

141.6 (5,000) |

1,830 (72.0) x 2,590 (102.0)x 2,337 (92.0) |

1,792 (3,950) |

6″ FLG |

|

Desiccant Dryer Performance |

||||||||||||||

|

Model |

Capacity -40°C Dew Point |

Heater kW |

Blower |

In/Out Connection in |

Width |

Dimensions |

Weight |

|||||||

|

Depth |

Height |

|||||||||||||

|

nm3/min |

scfm |

kW |

hp |

mm |

in |

mm |

in |

mm |

in |

kg |

lb |

|||

|

HL90 |

2.5 |

90 |

– |

— |

— |

1 NPT |

1,029 |

40.5 |

762 |

30.0 |

1,603 |

63.1 |

215 |

475 |

|

HL120 |

3.4 |

120 |

— |

— |

— |

1 NPT |

1,029 |

40.5 |

762 |

30.0 |

1,603 |

63.1 |

255 |

563 |

|

HL160 |

4.5 |

160 |

— |

— |

— |

11/ NPT |

1,130 |

44.5 |

813 |

32.0 |

1,679 |

66.1 |

321 |

707 |

|

HL200 |

5.7 |

200 |

— |

— |

— |

11/ NPT |

1,130 |

44.5 |

813 |

32.0 |

1,679 |

66.1 |

332 |

731 |

|

HL250 |

7.1 |

250 |

— |

— |

— |

11/ NPT |

1,232 |

48.5 |

813 |

32.0 |

1,697 |

66.8 |

394 |

869 |

|

HL300 |

8.5 |

300 |

— |

— |

— |

2NPT |

1,232 |

48.5 |

813 |

32.0 |

1,697 |

66.8 |

419 |

924 |

|

HL400 |

11.3 |

400 |

— |

— |

— |

2NPT |

1,334 |

52.5 |

919 |

36.2 |

1,722 |

67.8 |

506 |

1,115 |

|

HL500 |

14.2 |

500 |

— |

— |

— |

2 NPT |

1,435 |

56.5 |

1,008 |

39.7 |

2,096 |

82.5 |

709 |

1,564 |

|

HL600 |

17.0 |

600 |

— |

— |

— |

2 NPT |

1,435 |

56.5 |

1,078 |

42.4 |

2,096 |

82.5 |

755 |

1,664 |

|

HL800 |

22.7 |

800 |

— |

— |

— |

3 NPT |

1,626 |

64.0 |

1,302 |

51.3 |

2,226 |

87.6 |

915 |

2,017 |

|

HL1000 |

28.3 |

1,000 |

— |

— |

— |

3 NPT |

1,626 |

64.0 |

1,302 |

51.3 |

2,226 |

87.6 |

1,015 |

2,237 |

|

HL1200 |

34.0 |

1,200 |

— |

— |

— |

3 NPT |

1,626 |

64.0 |

1,302 |

51.3 |

2,226 |

87.6 |

1,100 |

2,424 |

|

HL1500 |

42.5 |

1,500 |

— |

— |

— |

4 FLG |

1,981 |

78.0 |

1,391 |

54.8 |

2,032 |

80.0 |

1,349 |

2,974 |

|

HL1800 |

51.0 |

1,800 |

— |

— |

— |

4 FLG |

2,134 |

84.0 |

1,540 |

60.6 |

2,334 |

91.9 |

1,771 |

3,905 |

|

HL2100 |

59.5 |

2,100 |

— |

— |

— |

4 FLG |

2,134 |

84.0 |

1,540 |

60.6 |

2,334 |

91.9 |

1,941 |

4,279 |

|

HL2700 |

76.4 |

2,700 |

— |

— |

— |

4 FLG |

2,134 |

84.0 |

1,550 |

60.8 |

2,334 |

91.9 |

2,234 |

4,926 |

|

HL3300 |

93.4 |

3,300 |

— |

— |

— |

6 FLG |

2,440 |

96.0 |

1,676 |

66.0 |

2,540 |

100.0 |

1,338* |

2,950* |

|

HL4000 |

113.3 |

4,000 |

— |

— |

— |

6 FLG |

2,440 |

96.0 |

1,676 |

66.0 |

2,540 |

100.0 |

1,361* |

3,000* |

|

HL5000 |

141.6 |

5,000 |

— |

— |

— |

6 FLG |

2,590 |

102.0 |

1,830 |

72.0 |

2,337 |

92.0 |

1,792* |

3,950* |

|

|

||||||||||||||

|

EH150 |

4.2 |

150 |

2.0 |

— |

— |

1 NPT |

1,130 |

44.5 |

813 |

32.0 |

1,676 |

66.0 |

344 |

758 |

|

EH200 |

5.7 |

200 |

3.0 |

— |

— |

11/ NPT |

1,232 |

48.5 |

813 |

32.0 |

1,702 |

67.0 |

414 |

913 |

|

EH250 |

7.1 |

250 |

3.0 |

— |

— |

11/ NPT |

1,334 |

52.5 |

889 |

35.0 |

1,727 |

68.0 |

508 |

1,119 |

|

EH300 |

8.5 |

300 |

3.0 |

— |

— |

11/ NPT |

1,334 |

52.5 |

889 |

35.0 |

1,727 |

68.0 |

540 |

1,191 |

|

EH400 |

11.3 |

400 |

4.5 |

— |

— |

2 NPT |

1,435 |

56.5 |

864 |

34.0 |

2,083 |

82.0 |

698 |

1,539 |

|

EH500 |

14.2 |

500 |

4.5 |

— |

— |

2 NPT |

1,435 |

56.5 |

864 |

34.0 |

2,083 |

82.0 |

774 |

1,707 |

|

EH600 |

17.0 |

600 |

6.0 |

— |

— |

3 NPT |

1,626 |

64.0 |

1,194 |

47.0 |

2,184 |

86.0 |

1,075 |

2,369 |

|

EH800 |

22.7 |

800 |

9.0 |

— |

— |

3 NPT |

1,626 |

64.0 |

1,194 |

47.0 |

2,184 |

86.0 |

1,216 |

2,681 |

|

EH1000 |

28.3 |

1,000 |

9.0 |

— |

— |

3 NPT |

1,994 |

78.5 |

1,219 |

48.0 |

2,032 |

80.0 |

1,380 |

3,043 |

|

EH1200 |

34.0 |

1,200 |

12.0 |

— |

— |

3 NPT |

1,994 |

78.5 |

1,219 |

48.0 |

2,032 |

80.0 |

1,490 |

3,285 |

|

EH1500 |

42.5 |

1,500 |

15.0 |

— |

— |

3 NPT |

2,134 |

84.0 |

1,397 |

55.0 |

2,337 |

92.0 |

2,032 |

4,480 |

|

EH1800 |

51.0 |

1,800 |

18.0 |

— |

— |

4 FLG |

2,134 |

84.0 |

1,524 |

60.0 |

2,337 |

92.0 |

2,248 |

4,956 |

|

EH2100 |

59.5 |

2,100 |

18.0 |

— |

— |

4 FLG |

2,134 |

84.0 |

1,524 |

60.0 |

2,337 |

92.0 |

2,427 |

5,350 |

|

EH3000 |

84.9 |

3,000 |

30.0 |

— |

— |

4 FLG |

2,438 |

96.0 |

1,854 |

73.0 |

2,540 |

100.0 |

3,515 |

7,750 |

|

EH4000 |

113.3 |

4,000 |

36.0 |

— |

— |

6 FLG |

2,591 |

102.0 |

2,134 |

84.0 |

2,337 |

92.0 |

4,965 |

10,950 |

|

EH5000 |

141.6 |

5,000 |

50.0 |

— |

— |

6 FLG |

3,048 |

120.0 |

2,311 |

91.0 |

2,464 |

97.0 |

6,009 |

13,248 |

|

EH6000 |

169.9 |

6,000 |

60.0 |

— |

— |

6 FLG |

3,353 |

132.0 |

2,413 |

95.0 |

2,616 |

103.0 |

7,120 |

15,696 |

|

EH8000 |

226.5 |

8,000 |

75.0 |

— |

— |

8 FLG |

3,962 |

156.0 |

2,565 |

101.0 |

2,667 |

105.0 |

8,122 |

17,910 |

|

|

||||||||||||||

|

HB150 |

4.2 |

150 |

3.0 |

0.75 |

1.0 |

1 NPT |

1,143 |

45.0 |

840 |

33.0 |

1,676 |

66.0 |

476 |

1,050 |

|

HB200 |

5.7 |

200 |

4.5 |

0.75 |

1.0 |

11/ NPT |

1,245 |

49.0 |

940 |

37.0 |

1,702 |

67.0 |

522 |

1,150 |

|

HB250 |

7.1 |

250 |

6.0 |

1.1 |

1.5 |

11/ NPT |

1,350 |

53.0 |

970 |

38.0 |

1,727 |

68.0 |

635 |

1,400 |

|

HB300 |

8.5 |

300 |

6.0 |

1.1 |

1.5 |

11/ NPT |

1,350 |

53.0 |

970 |

38.0 |

1,727 |

68.0 |

680 |

1,500 |

|

HB400 |

11.3 |

400 |

9.0 |

1.5 |

2.0 |

2 NPT |

1,450 |

57.0 |

1,220 |

48.0 |

2,108 |

83.0 |

862 |

1,900 |

|

HB500 |

14.2 |

500 |

12.0 |

1.5 |

2.0 |

2 NPT |

1,450 |

57.0 |

1,220 |

48.0 |

2,108 |

83.0 |

953 |

2,100 |

|

HB600 |

17.0 |

600 |

12.0 |

3.7 |

5.0 |

3 NPT |

1,620 |

64.0 |

1,500 |

59.0 |

2,235 |

88.0 |

1,270 |

2,800 |

|

HB800 |

22.7 |

800 |

18.0 |

3.7 |

5.0 |

3 NPT |

1,620 |

64.0 |

1,500 |

59.0 |

2,235 |

88.0 |

1,452 |

3,200 |

|

HB1000 |

28.3 |

1,000 |

24.0 |

5.6 |

7.5 |

3 NPT |

1,980 |

78.0 |

1,500 |

59.0 |

2,032 |

80.0 |

1,709 |

3,767 |

|

HB1200 |

34.0 |

1,200 |

24.0 |

5.6 |

7.5 |

3 NPT |

1,980 |

78.0 |

1,500 |

59.0 |

2,032 |

80.0 |

1,860 |

4,100 |

|

HB1500 |

42.5 |

1,500 |

30.0 |

11.2 |

15.0 |

3 NPT |

2,490 |

98.0 |

1,650 |

65.0 |

2,337 |

92.0 |

2,502 |

5,515 |

|

HB1800 |

51.0 |

1,800 |

36.0 |

11.2 |

15.0 |

4 FLG |

2,490 |

98.0 |

1,730 |

68.0 |

2,337 |

92.0 |

2,773 |

6,113 |

|

HB2100 |

59.5 |

2,100 |

45.0 |

11.2 |

15.0 |

4 FLG |

2,490 |

98.0 |

1,700 |

67.0 |

2,337 |

92.0 |

3,135 |

6,911 |

|

HB3000 |

84.9 |

3,000 |

60.0 |

14.9 |

20.0 |

6 FLG |

3,050 |

120.0 |

1,980 |

78.0 |

2,540 |

100.0 |

4,413 |

9,730 |

|

HB4000 |

113.3 |

4,000 |

80.0 |

18.7 |

25.0 |

6 FLG |

3,200 |

126.0 |

2,110 |

83.0 |

2,337 |

92.0 |

5,519 |

12,167 |

|

HB5000 |

141.6 |

5,000 |

100.0 |

22.4 |

30.0 |

6 FLG |

3,500 |

138.0 |

2,210 |

87.0 |

2,464 |

97.0 |

6,472 |

14,720 |

|

HB6000 |

169.9 |

6,000 |

125.0 |

22.4 |

30.0 |

6 FLG |

3,810 |

150.0 |

2,390 |

94.0 |

2,616 |

103.0 |

7,911 |

17,440 |

|

HB8000 |

226.5 |

8,000 |

175.0 |

29.8 |

40.0 |

8 FLG |

4,270 |

168.0 |

2,490 |

98.0 |

2,667 |

105.0 |

9,026 |

19,900 |

Dữ liệu hiệu suất theo ISO 7183: Máy sấy khí nén – Thông số kỹ thuật và thử nghiệm

Áp suất làm việc tối đa là 10,3 bar g (150 psig)

Chất hút ẩm được lắp đặt tại nhà máy trên tất cả các model ngoại trừ: HL3300-HL5000; EH3000-EH8000, HB3000-HB8000

Kích thước và trọng lượng là gần đúng

*Trọng lượng máy sấy hiển thị không bao gồm chất hút ẩm. Chất hút ẩm được vận chuyển riêng.

Địa chỉ: KĐT Ciputra, Phường Đông Ngạc, Quận Bắc Từ Liêm, TP. Hà Nội

Hotline 1: 098 194 1795 (24/7)

Email: david@adonggroup.com

Hotline 2: 096 778 6962 (24/7)

Email: thietbicongnghiepadong@gmail.com

Website: sullivan-palatek.vn

Địa chỉ: KĐT Ciputra, Phường Đông Ngạc, Quận Bắc Từ Liêm, TP. Hà Nội

Hotline 1: 098 194 1795 (24/7)

Email: david@adonggroup.com

Hotline 2: 096 778 6962 (24/7)

Email: thietbicongnghiepadong@gmail.com

Website: sullivan-palatek.vn

© Sullivan-Palatek Inc. • 2023 All Rights Reserved • Sitemap • www.sullivan-palatek.vn